Severe Service Isolation Ball Valves

Home » Severe Service Isolation Ball Valves

Severe Service Isolation Ball Valves

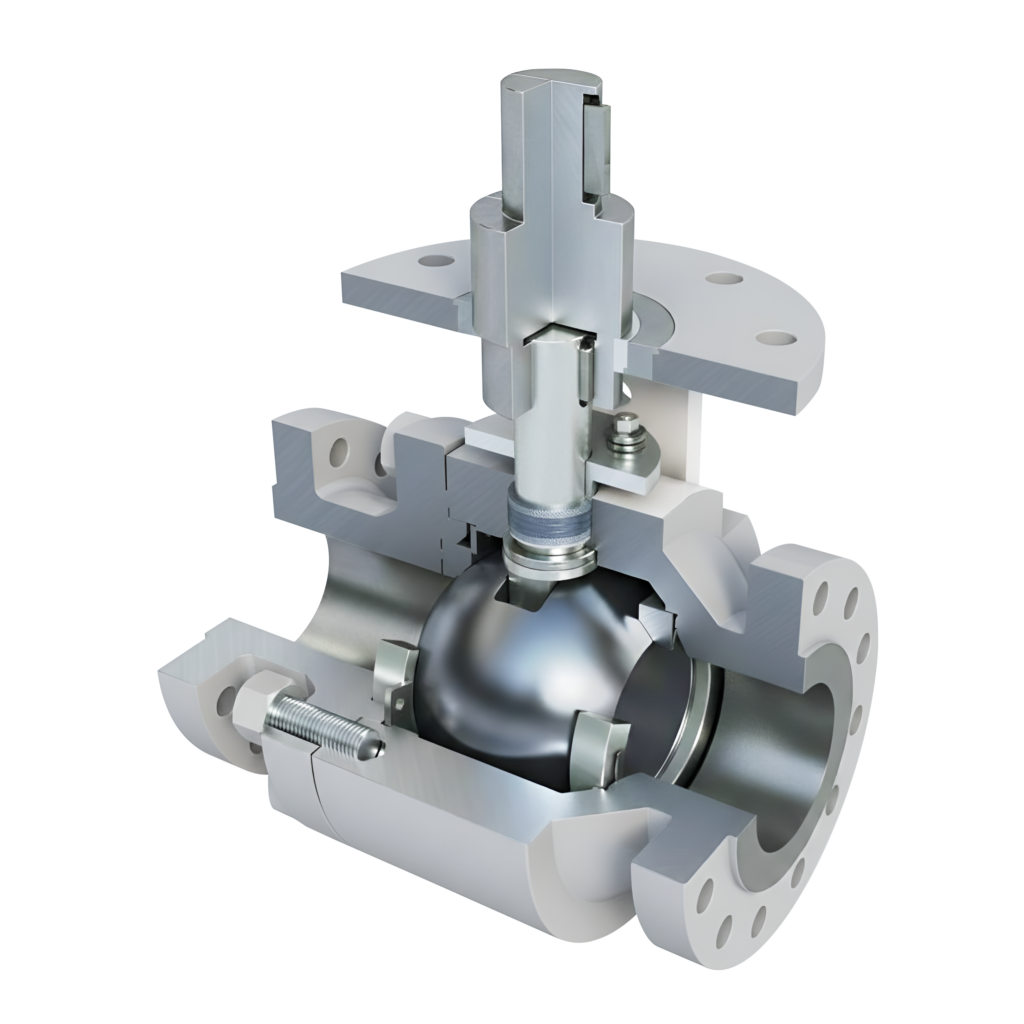

Severe Service Isolation Ball Valves are engineered for reliable shut-off in the most demanding operating conditions. Designed to handle high pressures, high temperatures, erosive and corrosive media, and frequent cycling, these valves deliver tight shut-off, long service life, and predictable performance where conventional isolation valves fail.

Magwen’s Severe Service Isolation Ball Valves combine robust mechanical design, precision metal-to-metal sealing by default, and advanced materials to ensure dependable isolation across critical applications in oil & gas production and processing, petrochemicals, refineries, power generation, metals and mining, chemical processing, hydrogen service, and other severe industrial environments.

Key design features focus on extending service life, minimizing unplanned downtime, reducing total cost of ownership, ensuring fire-safe performance, and preventing fugitive emissions.

Size Range: NPS 2” – 24” | DN50 – DN600

Pressure Rating: Up to ASME Class #2500 | Up to PN420

Materials Available: Carbon Steels, Low-Temperature Carbon Steels, Stainless Steels, Duplex & Super Duplex Stainless Steels, Nickel Alloys, CRA-clad constructions (Other materials available on request)

Body Construction: Split Body / Side-Entry, Top-Entry (engineered for in-line maintenance on request)

End Connections: Flanged (RF / RTJ), Butt-Weld (Other end connections engineered on request)

For more detailed technical information, please download the Product Catalog.

(Insert hyperlink to the downloads page on the underlined text)

The ball is supported by precision-engineered seats and allowed controlled axial movement under line pressure. Differential pressure forces the ball against the downstream seat, ensuring tight shut-off. This inherently pressure-assisted sealing principle enables reliable isolation without complex trunnion support, while maintaining a compact and cost-effective valve design.

For severe service duties, the valve is equipped with hardened metal seats and ball surfaces. Advanced hard-facing overlays (such as tungsten carbide or cobalt-based alloys) provide excellent resistance to erosion, corrosion, galling, and high-temperature degradation. This ensures consistent sealing performance under abrasive, flashing, or high-velocity flow conditions.

The seats are spring-loaded to maintain continuous contact with the ball during low-pressure, vacuum, and thermal cycling conditions. This ensures bi-directional tight shut-off across the full operating envelope

In the event of external fire exposure, non-metallic components degrade in a controlled manner, allowing the metal sealing surfaces to maintain isolation and comply with applicable fire-safe requirements.

The stem is designed with an internal shoulder that prevents ejection under line pressure, ensuring safe operation under abnormal pressure conditions.

An integrated anti-static design ensures electrical continuity between the ball, stem, and body, preventing the accumulation of static charge in hydrocarbon and hazardous services.

Fugitive emissions from the stem bore are controlled using live-loaded packing systems with Belleville washers. This maintains consistent sealing stress over time, compensates for wear and thermal expansion, and supports long-term emission control.

High-performance bearings isolate the stem from line media, reduce operating torque, and ensure smooth, repeatable valve operation throughout its service life.

The valve is provided with an ISO 5211 compliant mounting interface, allowing direct mounting of manual, pneumatic, hydraulic, or electric actuators, and enabling easy assembly, disassembly, or actuator replacement.

The stem-to-ball joint is designed for positive torque transmission with minimal hysteresis. Axial and rotational movement are precisely controlled to ensure accurate positioning and long-term mechanical integrity.

Clear visual indication of the valve’s open or closed position is provided at the stem drive end for safe and intuitive operation.

Typical Applications

- High-pressure isolation in oil & gas production and processing

- Refinery and petrochemical isolation services

- Erosive and corrosive process lines

- Hydrogen and alternative energy services

- Power generation and critical utility isolation

- Severe on/off service requiring reliable shut-off