Double Offset Butterfly Valve

Home » Double Offset Butterfly Valve

Double Offset Butterfly Valve

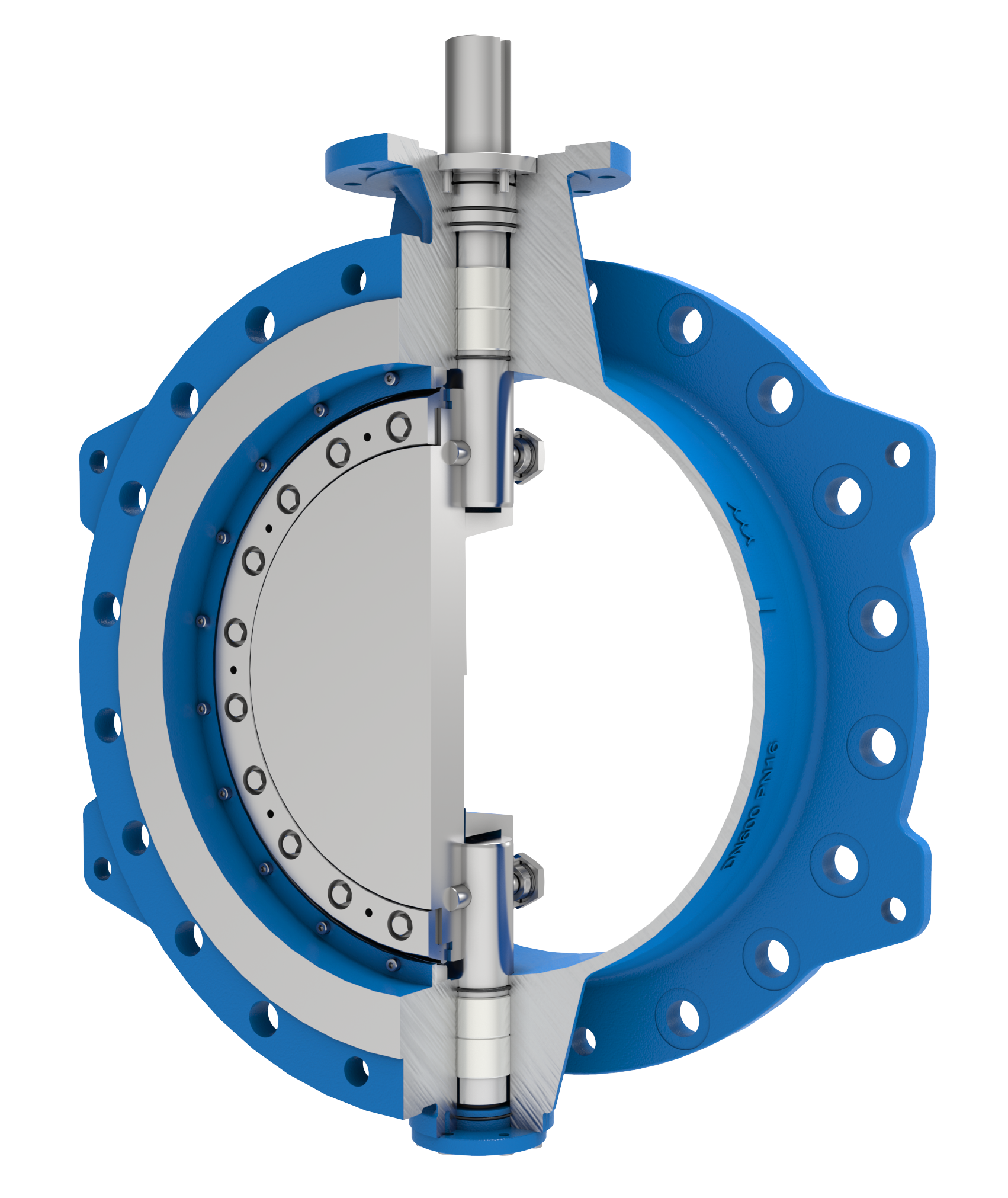

The Double Offset Butterfly Valve is the result of continuous evolution of centric butterfly valve design. Featuring offset operation geometries, the double offset butterfly valve uses ‘cam’ type motion of the disc to deliver reliable, low maintenance, long term operation with smoother operation and lower operating torques.

Magwen’s Double Offset Butterfly Valve range has diverse applications, with designs conforming to a variety of internationally accepted standards and project specific design changes, if requested or required.

Size Range: NPS 3”-120” | DN80-DN3000

Pressure Rating: Up-to PN64 | Up-to #300

Materials available: Ductile Iron, Carbon Steels, Stainless Steel grades, Exotic Alloys

For more detailed technical information, please download the Product Catalog.

Double Offset Design

1 of 12 Rigid Disc 2 of 12Stub Shaft

3 of 12Flush Retainer Ring and Flow-Through Disc

4 of 12Body Seat Ring

5 of 12Replaceable Resilient Seal Ring

6 of 12Protection of Bearing from line Media

7 of 12Life Time Lubricated Bearings

8 of 12Replacable Shaft Sealing

9 of 12Shaft Anti-Blowout Arrangement

10 of 12Corrosion Protection

11 of 12Direct-Mount Operator Flange

12 of 12The shaft’s position is given two ‘offsets’ from the pipe centerline. This results in a cam-type motion of the disc that leads to smoother operation, reduced operating torques with reduced wear and tear and enhanced service life.

Through specially developed assembly processes, we ensure that the disc position remains rigid for the whole service life. As a result, chattering is reduced and uneven wear and tear is avoided.

‘Stub’ or ‘Two-Piece’ shaft reduces overall weight and contributes to increased flow area.

Seal ring retainer is flush with the disc surface, further removing obstacles from the media flow path. For sizes DN1400 | NPS55 and above, a ‘Flow-Through’ disc is provided, further enhancing the valve’s Cv value.

Multiple material and construction options provided, to suit your exact application. Please download the catalog to learn more.

Flexible seal ring only made using WRAS approved EPDM, with a profile designed for reduced operating torque. For higher pressure grades or large valve sizes, a steel support ring is provided to enhance rigidity and service life. Please download the catalog to learn more.

Additional sealing is provided on either shaft to prevent any contact between bearings and line media. Results in extended bearing life and reduced maintenance frequency.

PTFE + Stainless Steel bearings used to support both shafts; inherently maintenance free, requiring no lubrication after usage.

Multi-stage replaceable sealing system is used to block all leak paths and make replacement of sealing during maintenance quick and easy.

Both shafts are designed to be ‘anti-blowout’, with nullified chances of ejections in case of severe line pressures.

Valves are provided with a fusion bonded epoxy coating as standard with a minimum coating of 250 microns.

Operator mount flange is designed as per ISO5211, to maximize compatibility with different operator types across different manufacturers.

Locks the position of the disc in either full open or full closed position, irrespective of presence of operator. Available optionally.