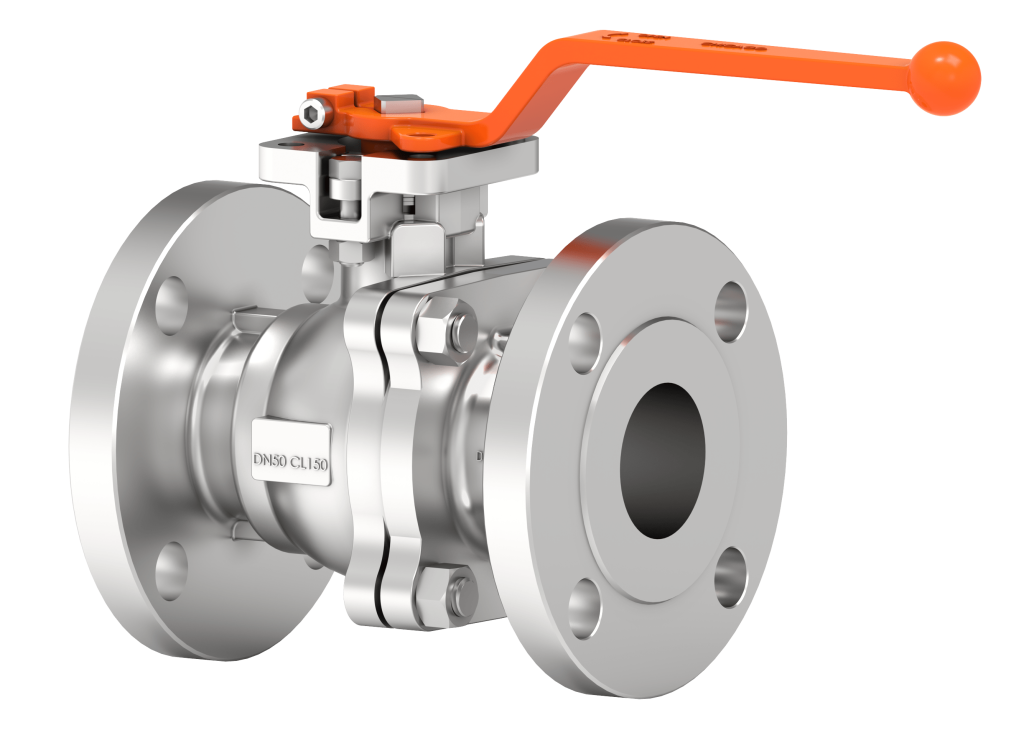

Floating Ball Valves

Home » Floating Ball Valves

Floating Ball Valves

Floating ball valves are some of the most versatile forms of isolation valves. Their simple construction and reliable sealing operation make them the ideal choice for a myriad of applications, ranging from oil and gas, petrochemicals, chemical processing, industrial applications, etc. Magwen’s high-tech floating ball valve range integrates many innovative design features that enhance its usable life, sealing reliability and usability for the user, while eliminating fugitive emissions.

Sizes: NPS 0.5” – 8” | DN15 – DN200

Pressure Ratings: Up-to PN50 | Up-to #300

Materials:

Body and trim – Carbon steel, various grades of stainless steel, exotic steel alloys, exotic non-ferrous alloys. Other materials may be available on request.

Seat – Reinforced P.T.F.E

For more detailed technical information, please download the Product Catalogue.

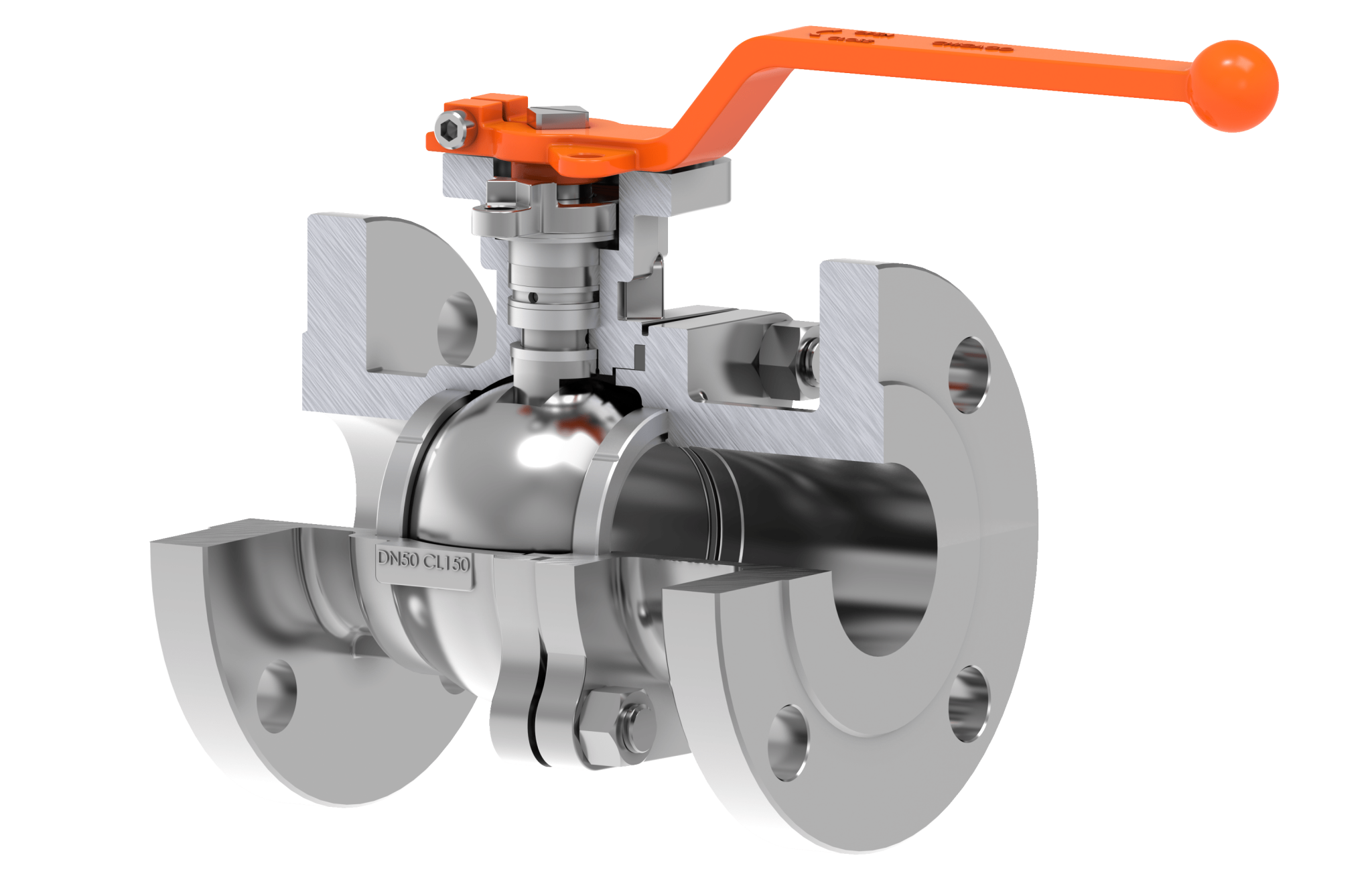

Live loaded stem packing

1 of 6Adjustable Gland Flange with ISO operator flange

2 of 6Anti-blowout stem

3 of 6Cavity Pressure Equalizing

4 of 6Anti-static features

5 of 6Handle

6 of 6The stem packing arrangement is provided with Belleville Washers, which makes the system ‘live loaded’ – a constant force acts on the packing, giving leak proof sealing and minimized fugitive emissions.

The packing gland is designed to allow tightening without the need to dismount the operator. To maximize operator compatibility, the operator mounting flange is designed as per internationally accepted ISO standards.

To eliminate chances of stem ejection, the valve is provided with anti-blowout features.

Magwen’s floating ball valve is provided with a unique seat design that automatically relieves trapped media into the pipeline, should there be pressure surges due to media expansion.

The valve is provided with an anti-static arrangement to facilitate an electrical pathway to prevent build up of free charge on the ball surface. This feature serves to increase safety of the pipe network.

The handle is given an ergonomic grip and is designed to minimize the operator’s effort.