Axial Flow Control Valves

Home » Axial Flow Control Valves

Axial Flow Control Valves

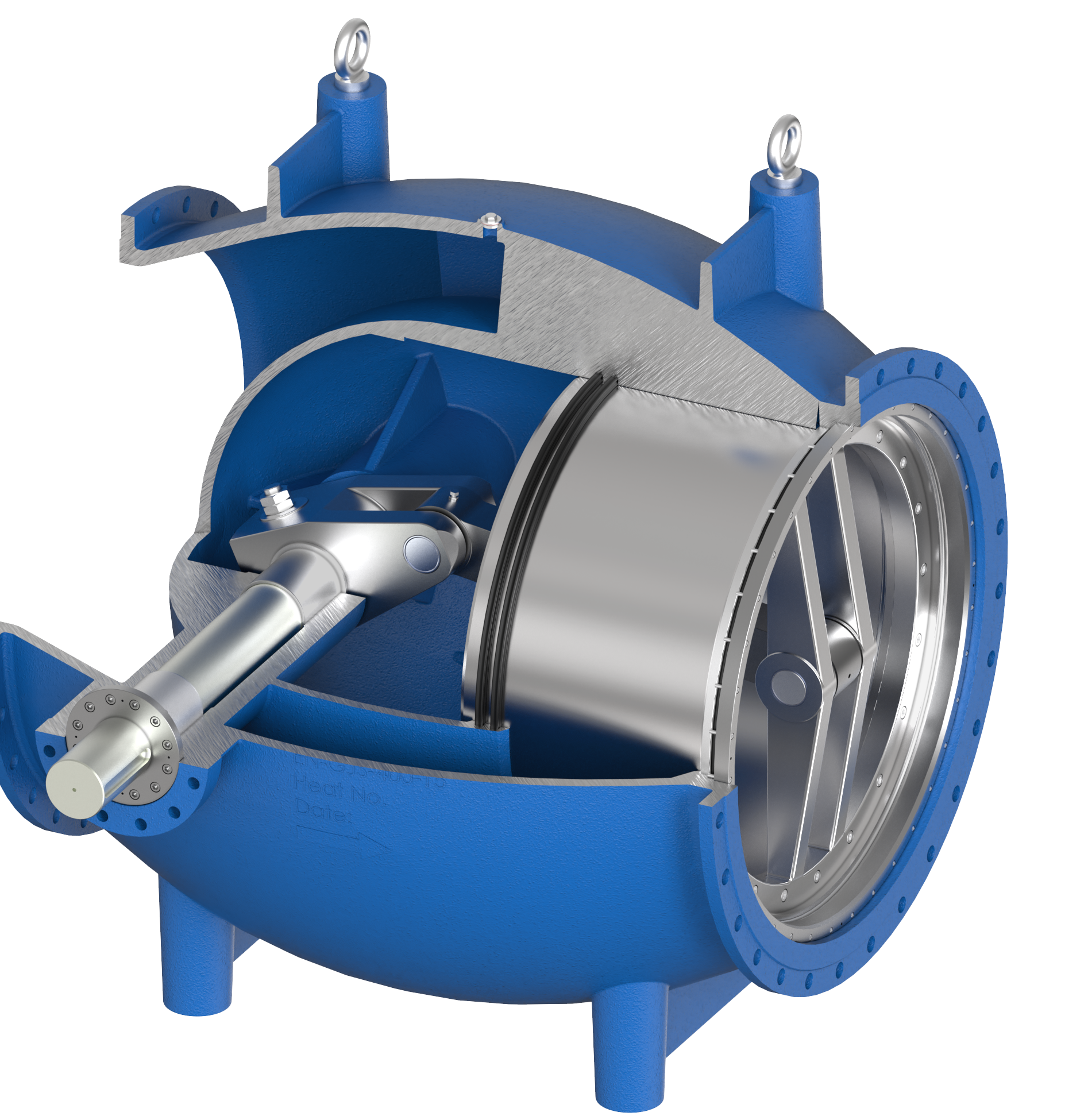

Axial Flow Control Valves are an effective solution for flow regulation of pipeline media. This regulation is achieved by manipulating the flow area using a ‘plunger’ or ‘piston’. These valves are also referred to as ‘Plunger Valves’ in some markets. Of all control valve solutions present, Axial Flow Control Valves provide the most linear and effective control flow characteristics. These valves are excellent in applications that require continuously variable throttling, significant pressure drops between upstream and downstream sides, dam discharge valves, reservoir inlet valves, high pressure regulation/shut off valves, etc.

Size Range: NPS 4” – 100” | DN100 – DN2500

Pressure Ratings: Up-to PN420 | Up-to #2500

Materials available: Ductile Iron, Carbon Steels, Stainless Steel grades, Exotic Alloys (other materials available on request)

For more detailed technical information, please download the Product Catalog.

Optimized Seal Life

1 of 7One-Piece Body

2 of 7Hard Faced Bronze Piston Guides

3 of 7Quad Ring Sealing for Piston

4 of 7Maintenance-free Bronze-Polymer compound bushes

5 of 7Double O-Ring Sealed Shaft

6 of 7Zero backlash Operation

7 of 7Flow of media is made tangential to the seal’s outer profile, reducing the chances of wear and enhancing usable life of the seal ring.

When permitted by design, the valve body is made from a rigid one-piece casting to eliminate chances of fugitive leak paths. For applications dealing with water, the body is given complete fusion bonded epoxy coating to prevent contamination of water during operation.

Linear motion of the plunger/piston is guided by use of 5 guide rails that surround the plunger/piston circumferentially. These rails are hard-faced using bronze (or other bearing materials, depending on application) and precisely machined to allow for jerk and jamming free operation of the valve.

Redundant ‘Quad-Ring’ cross section sealing is provided to seal the piston and achieve pressure balance effect. Unlike O-Rings, the ‘Quad-Ring’ seal eliminates chances of failure through torsion and operational wear and tear. Provided redundant as default for all size and pressure class combinations.

Friction between parts in the crank assembly is minimized by using maintenance-free, lifetime lubricated bronze-polymer bushes.

The main shaft bore is sealed using redundant O-ring seals, to eliminate all chances of fugitive emissions.

A recurring issue in typical Plunger valves is development of play between shaft and crank through use of impact-based connections like keyways. A unique shaft-crank-connecting rod connection geometry developed by Magwen ensures that operation of the valve will be zero-play for its usable life.